Liquid Ring Compressor vs. Screw Compressor

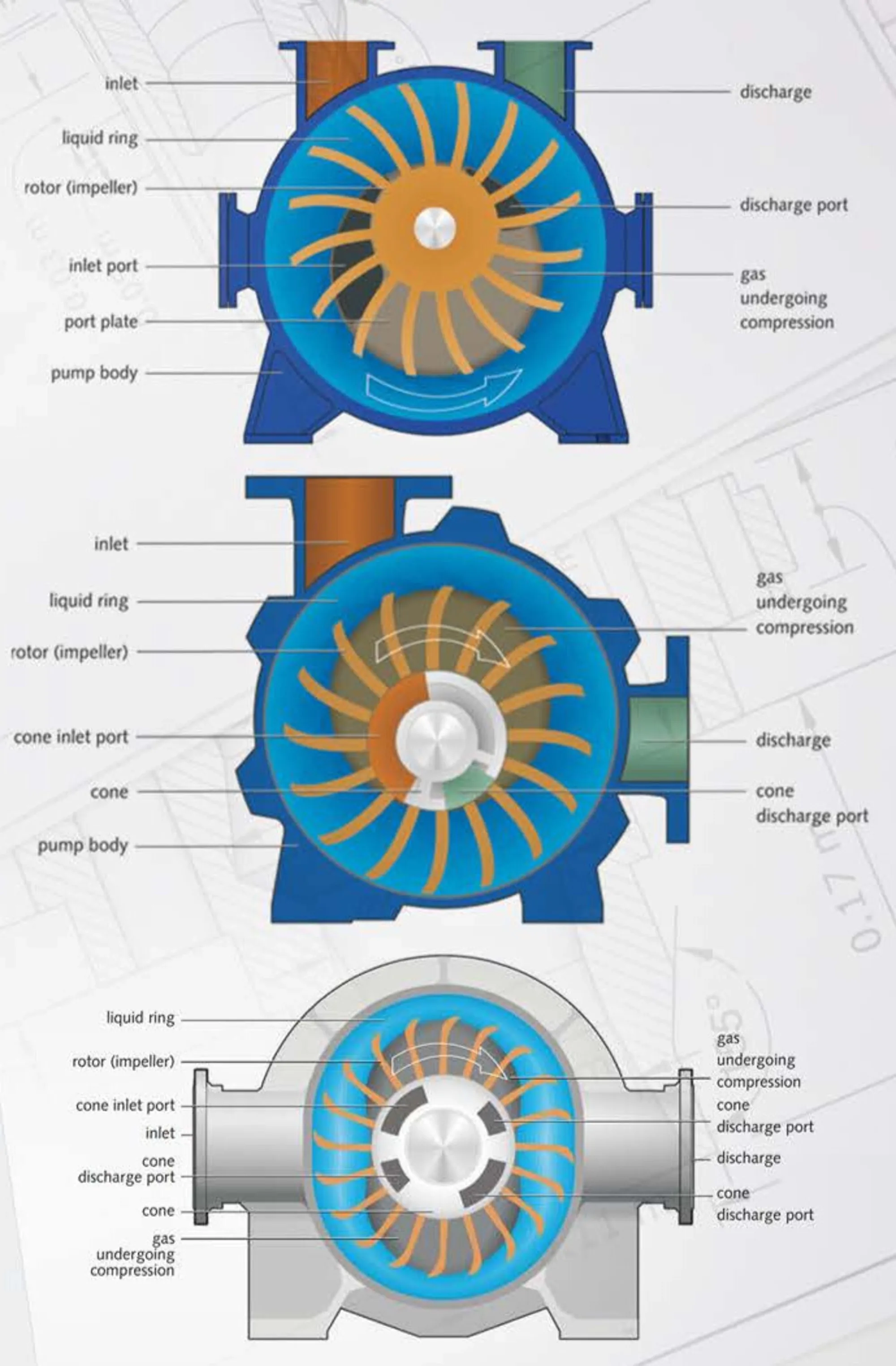

Design: LRCs use a liquid ring to compress gas, while screw compressors use two interlocking helical screws.

Efficiency: Screw compressors are generally more energy-efficient than LRCs, which can have efficiency limitations.

Application: LRCs are better suited for applications involving wet gases or gas mixtures with liquids, whereas screw compressors are preferred for dry gas applications

Liquid Ring Compressor for Hydrogen

LRCs are used in hydrogen applications due to their ability to handle gas mixtures and maintain isothermal conditions, which are essential for safely compressing hydrogen. Their design minimizes the risk of ignition, making them suitable for hydrogen processing and storage2.

Industries Using Liquid Ring Compressors

Chemical Processing: For handling corrosive gases and gas mixtures.

Oil and Gas: In flare gas recovery systems and other applications involving wet gases.

Food and Beverage: For vacuum packaging processes where maintaining low temperatures is crucial.

Pharmaceutical: In applications requiring oil-free compression and handling of vapors.

Benefits of Liquid Ring Compressors

Versatility: Suitable for a wide range of gases, including those with liquids and vapors.

Reliability: Robust design ensures long-term operation with minimal downtime.

Safety: Isothermal compression reduces the risk of overheating and ignition.

Low Maintenance: Fewer moving parts result in lower maintenance requirements.

Liquid Ring Compressors are a reliable and versatile solution for various industrial applications, offering durability, safety, and the ability to handle complex gas mixtures efficiently.